Guidelines for handling damaged built-in power supply of LED light pole screen

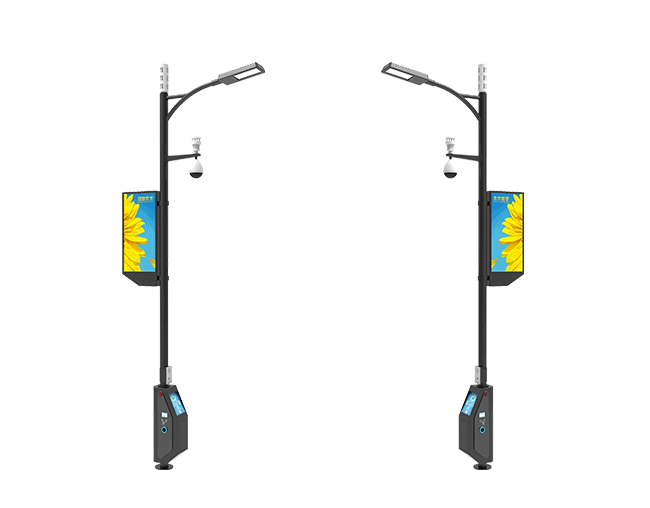

In the process of smart city construction, LED light pole screens have become an important carrier for the dissemination of urban public information with their advantages of real-time information release, energy saving and environmental protection. However, when the built-in power supply of the LED light pole screen is damaged, if it is not handled properly, it will not only cause the screen to fail to work properly, but also may cause safety hazards. Therefore, it is crucial to master scientific and standardized disposal methods.

Once the LED light pole screen is found to be abnormal, such as black screen, flickering, partial non-lighting, etc., which may be caused by power supply damage, power-off measures should be taken immediately. This is the most critical first step in the disposal process, which is related to personnel safety and prevention of further damage to equipment. During the specific operation, find the dedicated distribution box that controls the light pole screen and disconnect the power switch according to the operating specifications. If the location of the dedicated distribution box cannot be determined, contact the local power department or relevant management unit to assist in power off. Never perform any inspection or maintenance operations on the equipment without power off, because live work is very likely to cause electric shock accidents, and may also cause other parts of the equipment to suffer more serious damage due to problems such as short circuits.

After the power is turned off, the built-in power supply of the LED light pole screen needs to be fully checked to determine the specific cause and location of the damage. Check whether the power input line is damaged, aged, or short-circuited. You can visually observe whether there are cracks or burn marks on the outer skin of the wire, or you can gently pull the wire by hand to see if it is loose or falling off. If a problem with the wire is found, the wire of the same specification needs to be replaced in time. Secondly, check the appearance of the power module to see if there are obvious signs of physical damage such as bulging, deformation, and burning. If such a situation exists, it can be basically determined that the power module is damaged. You can also use a professional multimeter to measure the output voltage of the power supply and compare it with the normal working voltage parameters of the LED light pole screen. If the output voltage is abnormal, it can also indicate that the power supply is faulty. During the investigation, detailed records should be kept, including information such as fault phenomena and damaged parts, to provide accurate basis for subsequent repairs.

According to the results of the investigation, choose a reasonable maintenance plan. If only simple components such as the power input line or fuse are damaged, you can purchase components of the same specification for replacement on your own, provided that you have relevant electrical knowledge and operating skills. However, during the replacement process, the electrical safety specifications must be strictly followed to ensure safe operation. If it is determined that the power module is damaged, due to the complex internal structure of the power module, involving professional circuit design and electronic components, it is not recommended for non-professionals to disassemble and repair it by themselves. The manufacturer of the LED light pole screen or a professional maintenance service provider should be contacted for repair or replacement by professional technicians. When contacting the manufacturer or repairer, the previously recorded fault information should be provided in a timely manner so that the other party can quickly understand the situation, prepare the corresponding repair parts and tools, and improve the maintenance efficiency.

When it is necessary to replace the built-in power supply, ensure that the specifications of the new power supply are exactly the same as the original power supply, including parameters such as rated power, output voltage, and current. The replacement process should be operated by professional technicians and strictly follow the operating procedures. First, carefully remove the damaged power supply from the power supply installation position of the LED light pole screen, and pay attention to save the screws, connecting wires and other parts removed during the disassembly process to avoid loss. Then, fix the new power supply in the corresponding position according to the correct installation method, and accurately connect the input and output lines to ensure that the wiring is firm and the contact is good. After the replacement is completed, do not power on immediately. Check the installation and wiring of the power supply again. After confirming that there is no error, you can perform the power-on test.

Power-on test is an important part of verifying the effect of maintenance or replacement. After power on, observe whether the LED light pole screen can start normally, whether the screen display is clear and complete, and whether there are abnormal phenomena such as flickering and screen distortion. At the same time, use professional instruments to measure the output voltage, current and other parameters of the power supply again to ensure that they meet the normal working requirements of the equipment. If any problems are found during the test, the power should be turned off again immediately, and the repaired or replaced parts should be rechecked until the LED light pole screen can operate stably and normally.